Automatic Crusher Grease Lubrication System

BENEFITS OF AUTOMATIC GREASING SYSTEMS

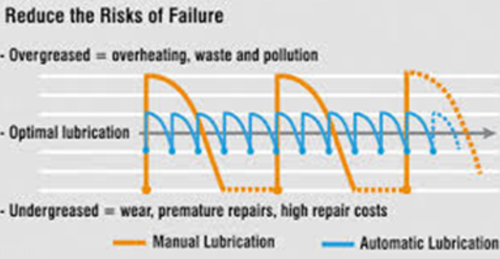

Automatic Greasing Systems ensure regular supply of lubricant at predefined intervals to all the greasing points when the machinery is in full operation. This results in uniform grease distribution across bearing surface, constant sealing and reduced grease consumption.

- Increase uptime & Profitability: No more expensive downtime or unwarranted repairs as a result of insufficient or irregular greasing.

- Less wear: Eliminates issues related to under greasing and irregular greasing. Presence of right qty of grease reduces the wear of moving parts and provides an effective barrier against moisture and dirt. It also protects these parts against corrosion.

- Lower maintenance cost: Uniform greasing pattern reduces wear and replacement or servicing of wear sensitive parts to a minimum. Longer replacement cycle of expensive parts results in a higher residual value of the vehicle or equipment.

- 100% greasing: Some greasing points on vehicles and equipments are located in hard to access areas. Greasing these points requires immense physical discomfort and these points may be left out during manual greasing cycles,. Automatic greasing relieves drivers, operators and service mechanics from dirty and even unsafe manual greasing for once and for all and ensures 100% greasing.

- More environmentally friendly: It controls the consumption of grease to exact requirement and avoid any wastage. Reduced grease consumption results in reduction of environmental waste.

Features :

- Timer Based System

- Independent Metering of Each Point

- Visual Fault Indication

- User Friendly